double shaft shredder machine manufacturers

Category:

Summary:

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, easy maintenance, safer, and more uerfriendly. 2. The crushing chamber adopts special materials and welding processes, making the machine structure more sturdy and with strong tearing ability. The blade is designed with high-quality alloy steel, and the rotor transmission is driven by a planetary reducer, with high torque and low speed to ensure smooth operation.

Keywords:

Plastic recyling machine

Service:

double shaft shredder machine manufacturers

Details

- Technical parameters

- Features

- Working Principle

- Mould display

- Details

- Application

-

- Commodity name: double shaft shredder machine manufacturers

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, easy maintenance, safer, and more uerfriendly. </br> 2. The crushing chamber adopts special materials and welding processes, making the machine structure more sturdy and with strong tearing ability. The blade is designed with high-quality alloy steel, and the rotor transmission is driven by a planetary reducer, with high torque and low speed to ensure smooth operation.

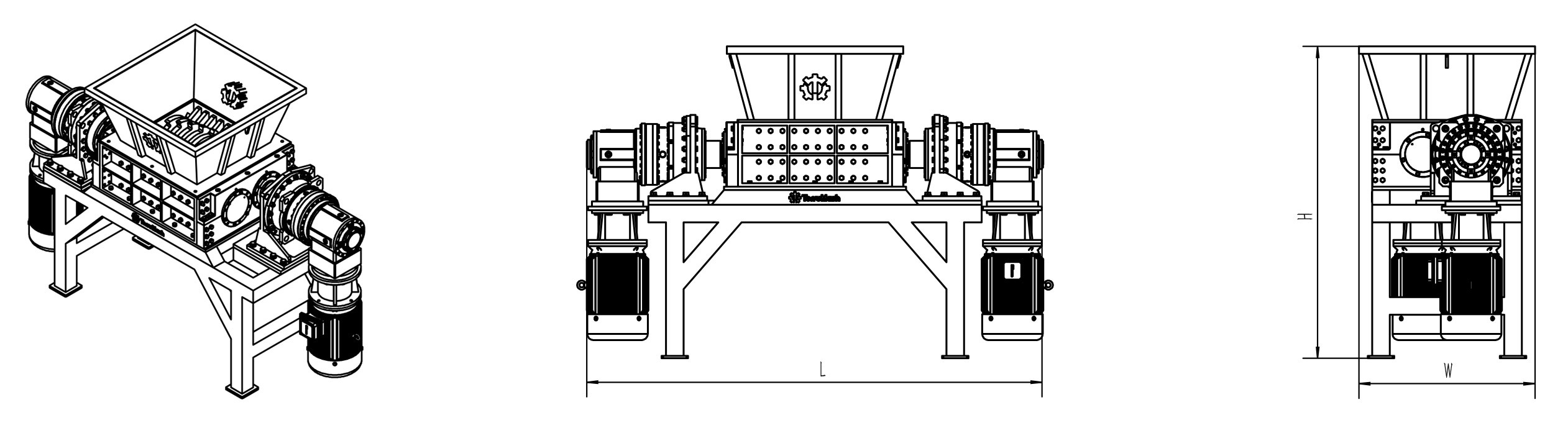

Double Shaft Shredder

HSZ series technical parameters

MODEL\SPEC HSZ800 HSZ1000 HSZ1200 HSZ1400 HSZ1600 Rotor diameter(mm) φ420 φ420 510 510 510 Rotor width(mm) 40 45 50 50 80 Number of Blades(pcs) 20 22 24 28 20 Main shaft speed(rpm) 14-23 14-23 10-18 10-18 8-15 Motor power( kw) 30x2 37x2 45x2 55x2 75x2 Chamber size(mm) 815x780 1015x780 1220x1000 1420x1000 1620x1000 Machine dimensions(mm) 3100x1020x2000 3500x1020x2000 4500x2300x2300 5000x2300x2300 6200x2300x2500 Weight(kg) 4500 8000 10500 12000 17000 MODEL HSZ800 HSZ1000 HSZ1200 HSZ1400 HSZ1600 L 3100 3500 4500 5000 6200 W 1020 1020 2300 2300 2300 H 2000 2000 2300 2300 2500

Double Shaft Shredder is an efficient and reliable industrial equipment, mainly used for shredding various waste materials. It consists of two rotating shafts and a set of blades, which can quickly and evenly shred waste materials into small particles for subsequent processing and recycling.

This Double Shaft Shredder has excellent performance and stable operation, and can handle many types of waste materials, such as plastics, paper, wood, metal, etc. It adopts an advanced dual-shaft design with greater shear and tearing force, and can easily cope with various hard materials.

The Double Shaft Shredder adopts an intelligent control system, which can automatically adjust the speed according to different waste materials, and is equipped with safety protection devices to effectively ensure the safety of operators.

Introducing our Double Shaft Shredder Machine, a powerful solution for comprehensive material shredding and recycling. Designed for heavy-duty applications, this robust machine is ideal for processing a variety of materials, including plastics, wood, paper, and metals. Whether you are in a recycling facility, manufacturing plant, or waste management operation, our shredder is engineered to meet your toughest demands.

The Double Shaft Shredder features dual rotating shafts equipped with high-strength blades that ensure efficient and uniform shredding. This innovative design reduces the risk of jamming and allows for the processing of larger, bulkier materials. With its powerful motor, the machine operates smoothly, providing consistent performance while minimizing energy consumption.

Safety is a priority; our shredder comes with built-in overload protection and emergency stop functions to ensure operator safety. The user-friendly control panel allows for easy adjustments and monitoring, making it simple to tailor the shredding process to your specific needs.

Built for durability and efficiency, the Double Shaft Shredder Machine not only reduces waste volume but also supports environmentally friendly practices. Invest in this essential tool to enhance your recycling operations and contribute to a more sustainable future!

-

Product Features

High yield

Low cost

Convenient maintenance

Safer

More use-friendly

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, convenient maintenance, safer and more use-friendly.

2. The crushing chamber adopts special materials and welding processes.making the machine structure more sturdy and with strong tearing ability. Theblade is designed with high-quality alloy steel, and the rotor transmission isdriven by a planetary reducer, with high torque and low speed to ensure smoothoperation.

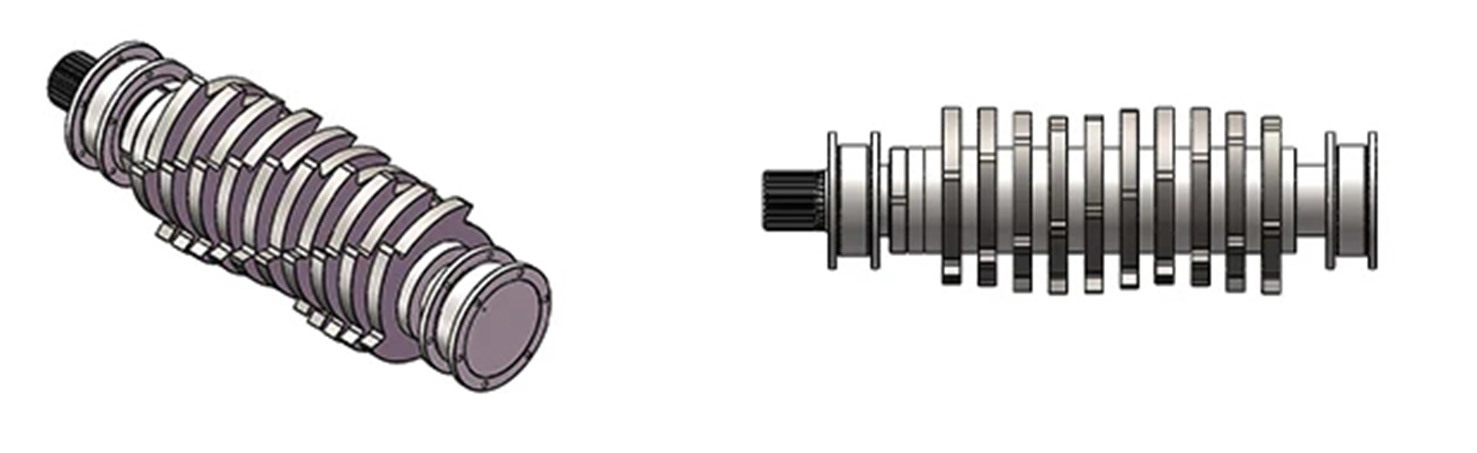

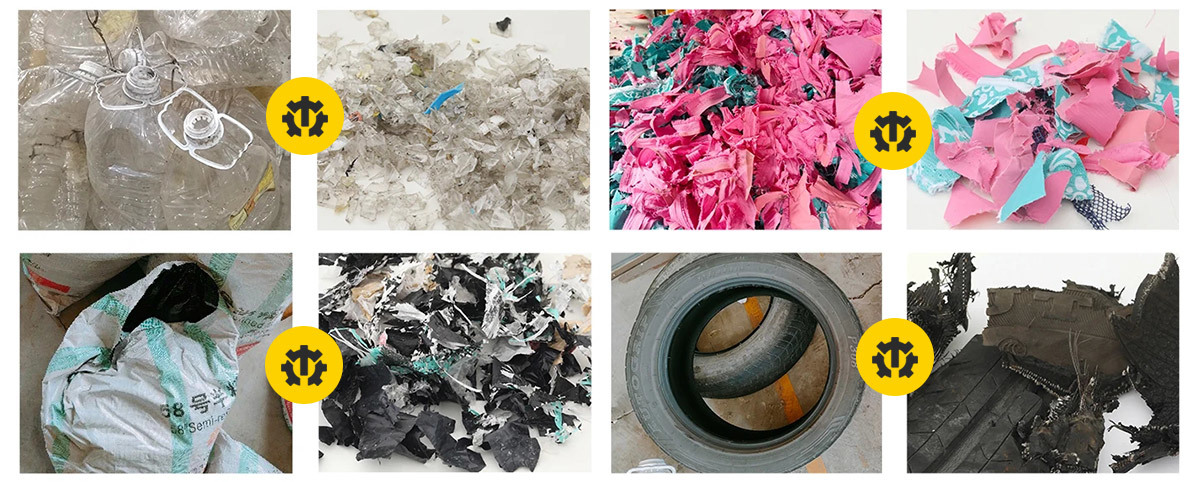

Applied Materials

Suitable materials for processing include:

-

Working Principle

1. Feed Hopper:

Put the material to be crushed, so as to prevent the material from splashing out.

2. Double Shaft Cutting System:

Using different blades according customers' material.

3. Power System:

We choose famous brands of motor in china, can also be configured according tocustomer needs.

4. Discharging Conveyor System:

Lt adopts independent power system, and that power system isintegrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

-

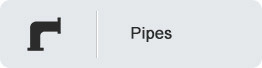

Double Shaft Shredder Mould Display

Low Speed, High Torque Shear, Strong Endurance Equipment,Low Loss, Low Noise, Energy Saving And Environmental Protection

-

Product Details

01 Pulverizing Chamber

Adopting special steel platewelding,exquisite welding tech-nology and become.lt is char-acterized by wear resistance,corrosion resistance and longservice life.

02 Rotors

Blade V-type spiral distribution,more uniform force. Blade ma-terial and structure: the use ofhigh-quality alloy steel, thereare a variety of materials anddifferent structures of the bladefor customers to choose.

03 Reducer

Adopt planetary speed reducer,spline connection,smooth trans-mission,low noise,with uniformforce, high torque, high fatigue strength.

-

Product Application

Pre

small single shaft shredder china

Exhibition

Recommended products

Message

Looking forward to communicating with you, a demand is the beginning of our understanding of you, but also the beginning of our establishment of cooperation.