china heavy duty plastic crusher

Category:

Summary:

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, convenient maintenance, safer and more user-friendly. 2. The body adopts a special steel welded structure, which is more sturdy and has strong tearing ability. The rotor adopts a V-shaped design, driven by a hard tooth reducer, with high torque and low speed.

Keywords:

Plastic recyling machine

Service:

china heavy duty plastic crusher

Details

- Technical parameters

- Features

- Working Principle

- Mould display

- Details

- Application

-

- Commodity name: china heavy duty plastic crusher

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, convenient maintenance, safer and more user-friendly.</br> 2. The body adopts a special steel welded structure, which is more sturdy and has strong tearing ability. The rotor adopts a V-shaped design, driven by a hard tooth reducer, with high torque and low speed.

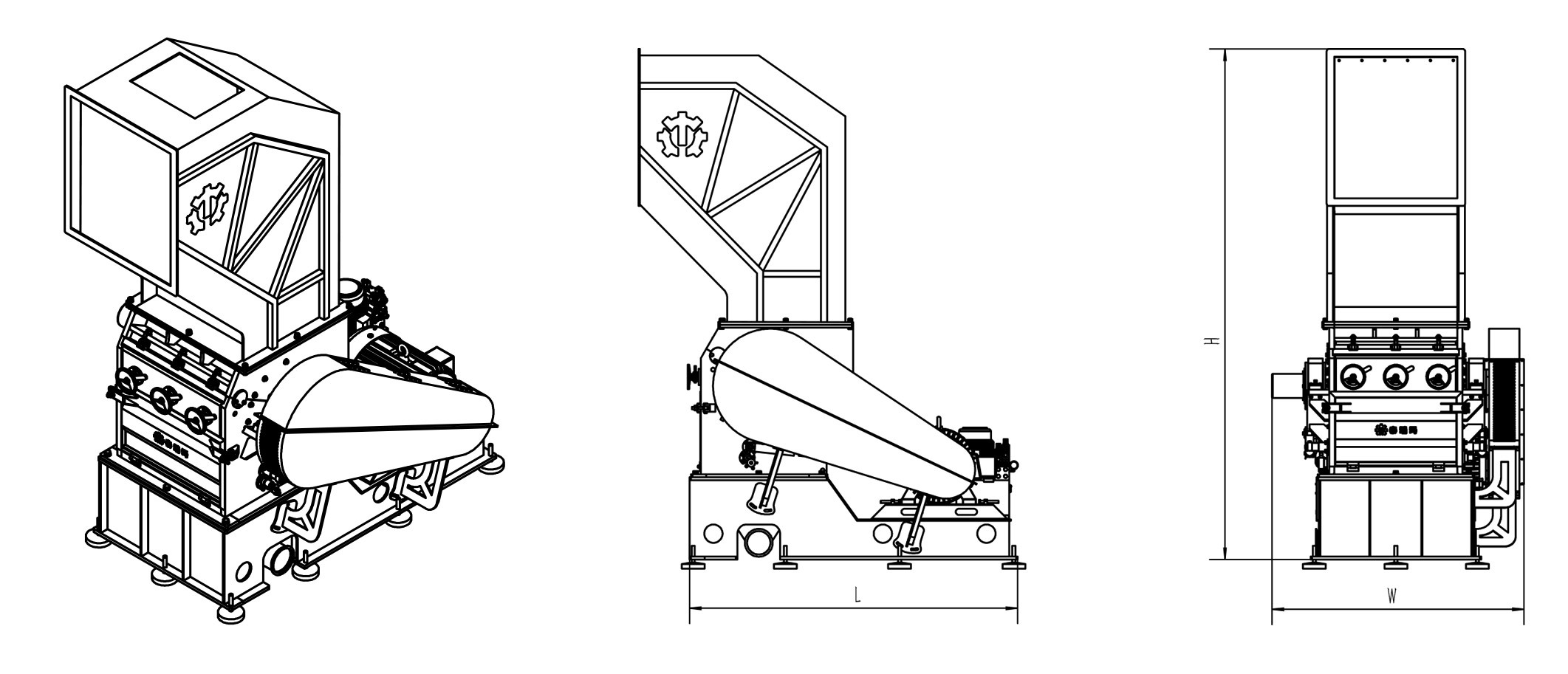

HFS Series- Heavy Duty Crusher

HFS series technical parameters

MODEL\SPEC HFS800/600 HFS1000/600 HFS1200/600 HFS1400/600 HFS1200/800 Rotor diameter(mm) φ600 φ600 φ600 φ600 φ800 Rotor width(mm) 800 1000 1200 1400 1200 Main shaft speed(rpm) 520 520 520 520 420 Stator knives(pcs) 2 2/3 2/3 2/3 2/3 Rotor knives(pcs) 3/5 5/7 5/7 5/7 5/7/9 Motor power(kw) 37/55 55/75 75/90 110/132 110/132 Hydraulic power( kw) 1.5 1.5 1.5 3 3 Feeding size(mm) 800x930 1000x930 1200x1000 1400x1000 1200*1100 Screen holes diameter(mm) >6 >6 >6 >10 >10 Machine dimensions(mm) 2200x1660x3420 2300x1860x3420 2300x2180x3520 2300x2400x3520 2300x2200x3720 Weight( kg) 3700 4300 5200 6500 8000 MODEL HFS800/600 HFS1000/600 HFS1200/600 HFS1400/600 HFS1200/800 L 2200 2300 2300 2300 2300 W 1660 1860 2180 2200 2400 H 3420 3420 3520 3520 3720 C 930 930 1000 1000 1100 D 800 1000 1200 1400 1200

Heavy Duty Crusher is a machine equipment used to crush large materials. It has a strong crushing capacity and is suitable for materials of various hardness and thinness, such as rocks, ores, construction waste, etc. The product is manufactured with advanced technology and high-quality materials, and is efficient, safe and reliable. It can be customized according to customer needs and can achieve the crushing of materials of various particle sizes and shapes. Heavy Duty Crusher is widely used in construction, metallurgy, chemical industry and other industries, and can play an important role in construction sites, mining sites and other occasions. At the same time, the product is also energy-saving and environmentally friendly, in line with the requirements of modern society for sustainable development. It is highly competitive in both performance and quality, and is your trustworthy choice.Introducing our Heavy Duty Plastic Crusher, engineered for robust performance in plastic recycling and waste management. This industrial-grade machine is designed to efficiently crush a wide range of plastic materials, including bottles, containers, and films, making it an indispensable asset for recycling facilities, manufacturing plants, and warehouses.

Constructed with a strong, durable frame, the Heavy Duty Plastic Crusher features high-quality, wear-resistant blades that provide superior cutting capability. Its powerful motor ensures consistent performance, allowing it to handle tough materials with ease. The crusher’s innovative design minimizes noise and vibration, ensuring a quieter operation while maximizing efficiency.

Equipped with advanced safety features, including an automatic shut-off system and overload protection, this crusher prioritizes operator safety during operation. The user-friendly control panel allows for easy adjustments and monitoring, making it simple to tailor the machine to specific processing requirements.

Designed for high throughput, the Heavy Duty Plastic Crusher significantly reduces plastic waste, helping businesses improve their recycling efforts and contribute to a more sustainable environment. Invest in this powerful machine today and enhance your plastic processing capabilities with efficiency and reliability!

-

Product Features

High yield

Low cost

Convenient maintenance

Safer

More use-friendly

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, convenient maintenance, safer and more use-friendly.

2. The body adopts a special steel welded structure, which is more sturdy and has strong tearing ability. The rotor adopts a V-shaped design, driven by a hard tooth reducer, with high torque and low speed.Applied Materials

Suitable materials for processing include:

-

Working Principle

1. Feed Hopper:

Put the material to be crushed, so as to prevent the material from splashing out

2. Heavy Duty Crusher Cutting System:

Using different blades according customers' material.

3. Power System:

We choose famous brands of motor in china, can also be configured according tocustomer needs.

4. Discharging Conveyor System:

Lt adopts independent power system, and that power system isintegrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

-

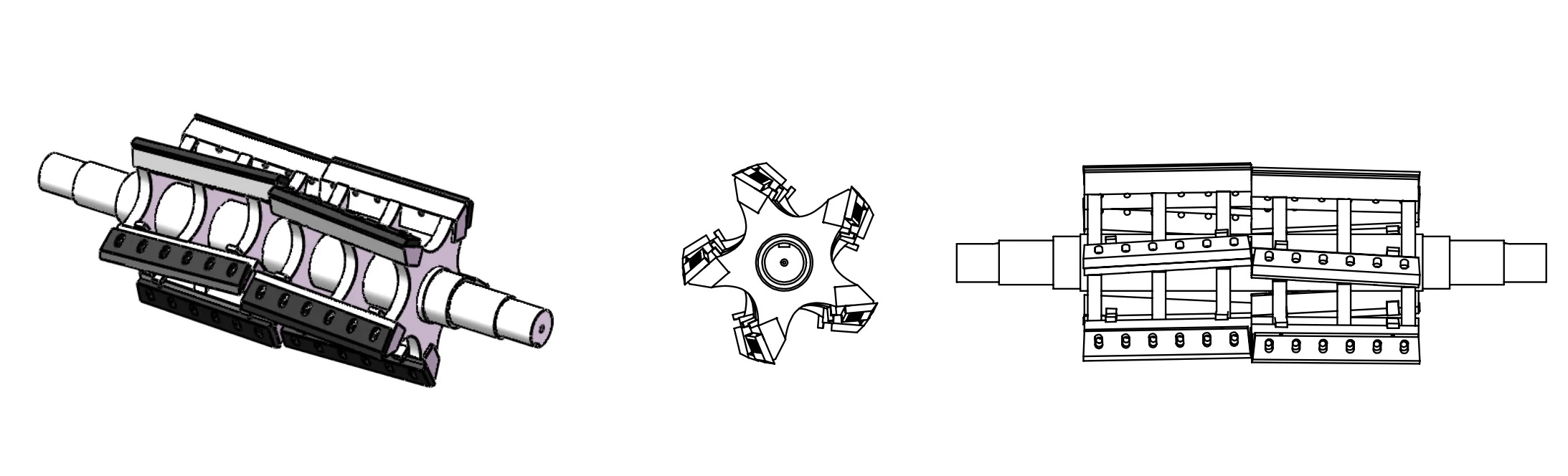

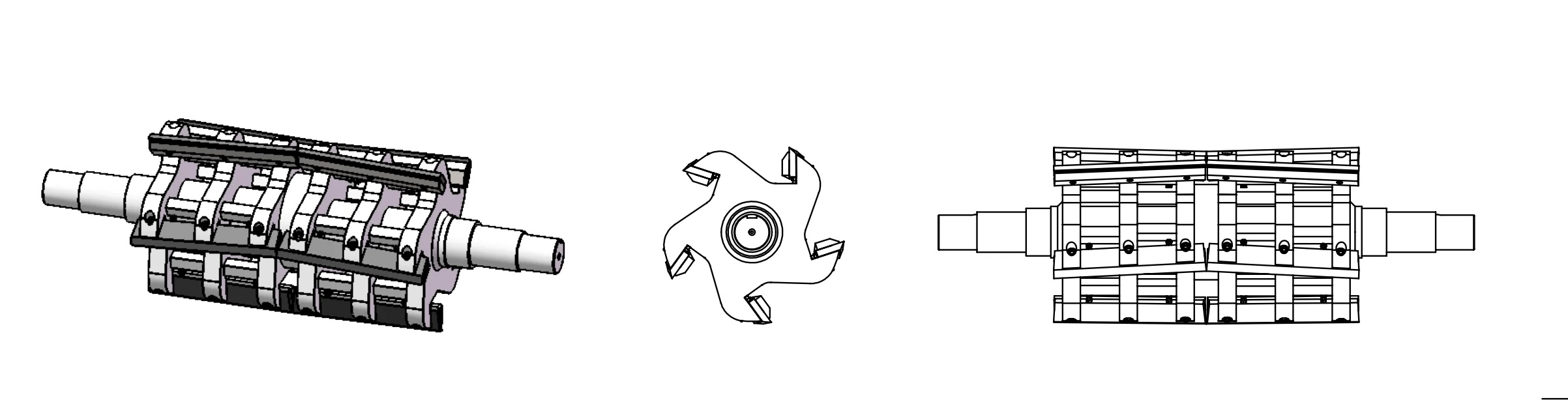

Heavy Duty Crusher Mould Display

1. Staggered knife:suitable for electronic film, softer material 2. Side-by-side knife:suitable for shredder material, secondary crushing

2. Side-by-side knife:suitable for shredder material, secondary crushing

-

Product Details

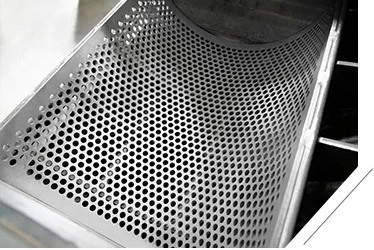

01 Sieve Mesh

According to different needs, dif-ferent mesh sizes can be replaced.The replacement of the screen is driven by hydraulic pressure, which better solves the shortage of manpower and the safety haz-ards caused by the replacement of the screen.

02 Bearing Seat

Adopting a well-known brand high-strength bearing for external installation, separated from crushed materials, to prevent material from entering the bearing and damaging the bearing, effectively reducing damage to the box and protecting the rotor.

03 Hydraulic Station

Hydraulic opening and closing device: blade maintenance and screen replacement, driven by hy-draulic pressure, can quickly and conveniently open the box and screen frame.

04 Rotor

The knife V arrangement effective-ly forms two-way shear, so that the material is concentrated in the middle, it is very good to avoid the accumulation of materials on both sides, and effectively reduce the wear on both sides of the box.

-

Product Application

Next

Pre

None

Next

Exhibition

Recommended products

Message

Looking forward to communicating with you, a demand is the beginning of our understanding of you, but also the beginning of our establishment of cooperation.