best double shaft shredder machine

Category:

Summary:

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, easy maintenance, safer, and more uerfriendly. 2. The crushing chamber adopts special materials and welding processes, making the machine structure more sturdy and with strong tearing ability. The blade is designed with high-quality alloy steel, and the rotor transmission is driven by a planetary reducer, with high torque and low speed to ensure smooth operation.

Keywords:

Plastic recyling machine

Service:

best double shaft shredder machine

Details

- Technical parameters

- Features

- Working Principle

- Mould display

- Details

- Application

-

- Commodity name: best double shaft shredder machine

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, easy maintenance, safer, and more uerfriendly. </br> 2. The crushing chamber adopts special materials and welding processes, making the machine structure more sturdy and with strong tearing ability. The blade is designed with high-quality alloy steel, and the rotor transmission is driven by a planetary reducer, with high torque and low speed to ensure smooth operation.

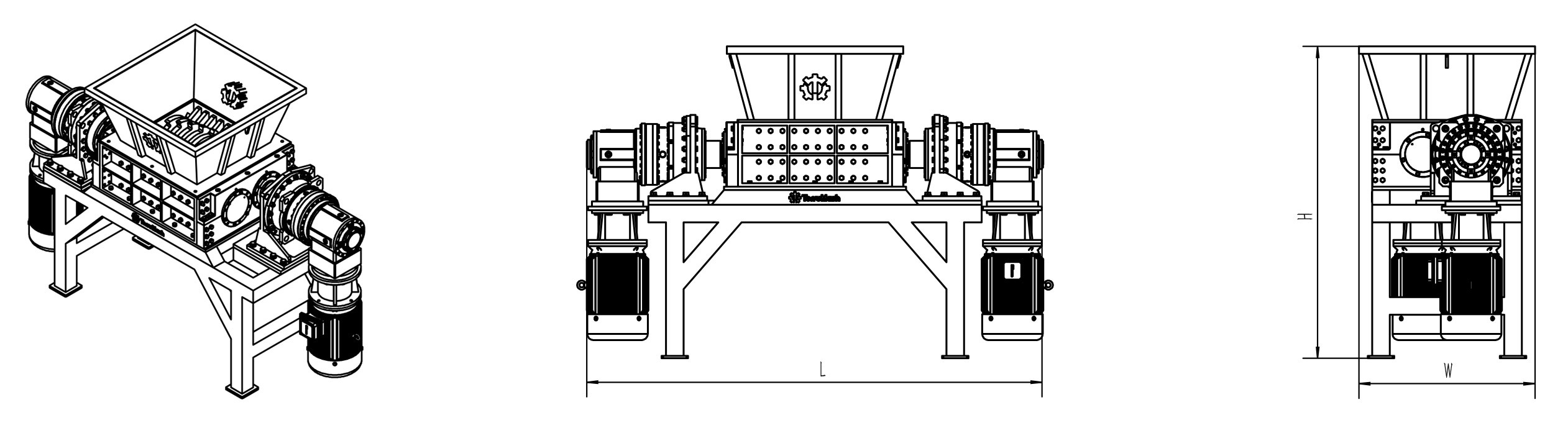

HSZ Series - Double Shaft Shredder

HSZ series technical parameters

MODEL\SPEC HSZ800 HSZ1000 HSZ1200 HSZ1400 HSZ1600 Rotor diameter(mm) φ420 φ420 510 510 510 Rotor width(mm) 40 45 50 50 80 Number of Blades(pcs) 20 22 24 28 20 Main shaft speed(rpm) 14-23 14-23 10-18 10-18 8-15 Motor power( kw) 30x2 37x2 45x2 55x2 75x2 Chamber size(mm) 815x780 1015x780 1220x1000 1420x1000 1620x1000 Machine dimensions(mm) 3100x1020x2000 3500x1020x2000 4500x2300x2300 5000x2300x2300 6200x2300x2500 Weight(kg) 4500 8000 10500 12000 17000 MODEL HSZ800 HSZ1000 HSZ1200 HSZ1400 HSZ1600 L 3100 3500 4500 5000 6200 W 1020 1020 2300 2300 2300 H 2000 2000 2300 2300 2500

Double Shaft Shredder is a special equipment, mainly used for shredding waste items, discarded materials, electronic waste, etc., so as to facilitate subsequent reuse or processing. It has a double-axis side-by-side structure, with staggered blades between the two axes, and shredding of items through high-speed rotation.

The product is made of high-strength alloy steel and has the characteristics of wear resistance, corrosion resistance, and strong pressure resistance. At the same time, the double-axis design can effectively improve the shredding efficiency and meet the shredding needs of different items by adjusting the blade spacing and angle.

Double Shaft Shredder is also equipped with advanced control systems and safety devices to ensure stability and safety during use. It can be widely used in recycling processing, resource utilization, environmental protection and other fields.

Introducing our Double Shaft Shredder Machine, engineered for unparalleled efficiency and versatility in material processing. This industrial-grade shredder is designed to handle a wide array of materials, including plastics, metals, rubber, and organic waste, making it an essential asset for recycling facilities and waste management operations.

The unique double shaft configuration features two parallel shafts that rotate in opposite directions, allowing for a powerful and effective shredding process. This design minimizes the risk of material jams while providing high torque, ensuring consistent performance even with dense and challenging materials. The heavy-duty blades, crafted from premium steel, are designed for durability and long-lasting use, ensuring reliable operation over time.

Equipped with advanced technology, our Ddouble shaft shredder machine offers adjustable speed settings and a user-friendly control panel, making it easy to tailor operations to meet specific processing needs. Safety features, including emergency stop buttons and overload protection, enhance operational security, ensuring a safe working environment.

Compact yet robust, this shredder is perfect for both large-scale industrial applications and smaller recycling initiatives. Invest in our Double Shaft Shredder Machine and take a significant step towards more efficient waste reduction and recycling today!

-

Product Features

High yield

Low cost

Convenient maintenance

Safer

More use-friendly

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, convenient maintenance, safer and more use-friendly.

2. The crushing chamber adopts special materials and welding processes.making the machine structure more sturdy and with strong tearing ability. Theblade is designed with high-quality alloy steel, and the rotor transmission isdriven by a planetary reducer, with high torque and low speed to ensure smoothoperation.

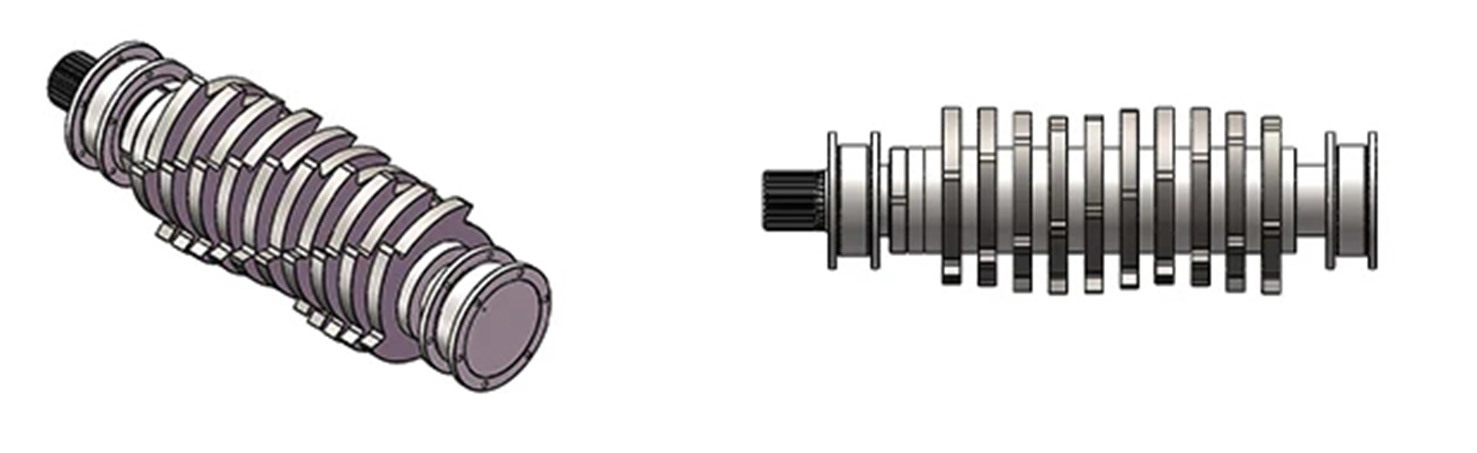

Applied Materials

Suitable materials for processing include:

-

Working Principle

1. Feed Hopper:

Put the material to be crushed, so as to prevent the material from splashing out.

2. Double Shaft Cutting System:

Using different blades according customers' material.

3. Power System:

We choose famous brands of motor in china, can also be configured according tocustomer needs.

4. Discharging Conveyor System:

Lt adopts independent power system, and that power system isintegrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

-

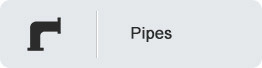

Double Shaft Shredder Mould Display

Low Speed, High Torque Shear, Strong Endurance Equipment,Low Loss, Low Noise, Energy Saving And Environmental Protection

-

Product Details

01 Pulverizing Chamber

Adopting special steel platewelding,exquisite welding tech-nology and become.lt is char-acterized by wear resistance,corrosion resistance and longservice life.

02 Rotors

Blade V-type spiral distribution,more uniform force. Blade ma-terial and structure: the use ofhigh-quality alloy steel, thereare a variety of materials anddifferent structures of the bladefor customers to choose.

03 Reducer

Adopt planetary speed reducer,spline connection,smooth trans-mission,low noise,with uniformforce, high torque, high fatigue strength.

-

Product Application

Pre

quality twin shaft shredder machine

Exhibition

Recommended products

Message

Looking forward to communicating with you, a demand is the beginning of our understanding of you, but also the beginning of our establishment of cooperation.