cheap small single shaft shredder

Category:

Summary:

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, convenient maintenance, safer and more user-friendly. 2. The body adopts a special steel welded structure, which is more sturdy and has strong tearing ability. The rotor adopts a V-shaped design, driven by a hard tooth reducer, with high torque and low speed.

Keywords:

Plastic recyling machine

Service:

cheap small single shaft shredder

Details

- Technical parameters

- Features

- Working Principle

- Mould display

- Details

- Application

-

- Commodity name: cheap small single shaft shredder

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, convenient maintenance, safer and more user-friendly.</br> 2. The body adopts a special steel welded structure, which is more sturdy and has strong tearing ability. The rotor adopts a V-shaped design, driven by a hard tooth reducer, with high torque and low speed.

HDZ Series-Single Shat Shredder

HDZ series technical parameters

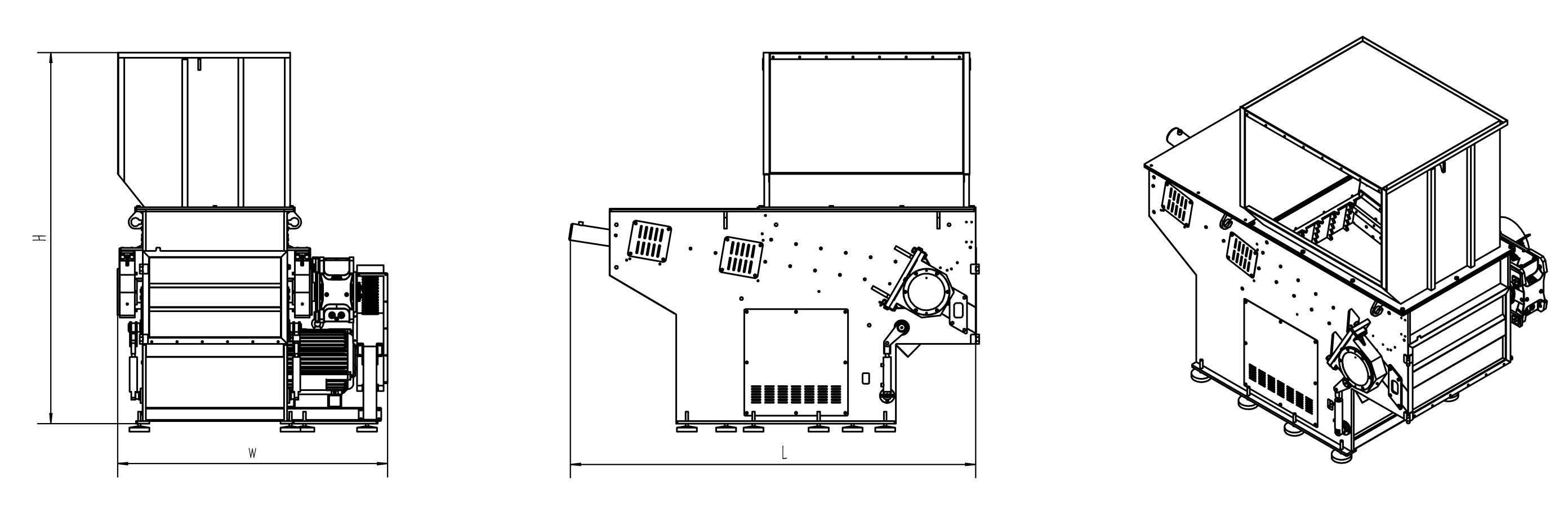

MODEL\SPEC HDZ600 HDZ800 HDZ1000 HDZ1200 HDZ1400 HDZ1600 HDZ1800 Rotor diameter(mm) φ300 φ400/450 φ450 φ450 φ450/520 φ580/630 φ580/630 Rotor width(mm) 600 820 1030 1230 1450 1650 1850 Main shaft speed(rpm) 73 73 73 73 73 73 73 Stator knives(pcs) 2 2 3 3 4 5 6 Rotor knives(pcs) 30/45 34/51 42/63 54/81/108 81/108/132 70/105/140 86/129/172 Motor power(kw) 22 37/45 55 75 90 75x2 90x2 Hydraulic power( kw) 5.5 5.5 5.5 5.5 7.5 7.5 7.5 Screen holes diameter(mm) >20 >20 >20 >20 >20 >20 >20 Machine dimensions(mm) 1780x1400x1900 2400x1800x2500 2800x2000x2800 3350x2350x3000 3350x2600x3000 3800x3400x3600 4100x3400*3600 Weight( kg) 2800 3700 5000 6800 8300 11000 14000 MODEL HDZ600 HDZ800 HDZ1000 HDZ1200 HDZ1400 HDZ1600 HDZ1800 L 1780 2400 2800 3350 3350 3800 4100 W 1400 1800 2000 2350 2600 3400 3400 H 1900 2500 2800 3000 3000 3600 3600

Single Shaft Shredder is a device specially used for shredding various materials. It uses a single blade to cut and tear the materials under high-speed rotation, thereby crushing and decomposing the materials. This product has the characteristics of simple structure, convenient operation, and strong processing capacity. It is suitable for crushing and processing various materials such as waste plastics, rubber, wood, paper, textiles, etc. Single Shaft Shredder can effectively reduce the volume of waste and reduce processing costs. It also provides convenience for subsequent recycling. This product is widely used in garbage treatment plants, renewable resource recovery companies and other fields.Introducing our Small Single Shaft Shredder, the ideal solution for efficient and compact material processing. Perfectly designed for smaller operations, this shredder excels in handling a variety of materials, including plastics, wood, paper, and light metals, making it an essential tool for recycling centers, workshops, and small-scale manufacturers.

The innovative single shaft design features a robust, rotating blade that efficiently shreds materials into uniform pieces. With a powerful motor and high torque capabilities, this shredder ensures smooth operation and can tackle even challenging materials with ease. Its compact footprint allows it to fit seamlessly into tight spaces, making it a practical choice for facilities with limited room.

Equipped with an intuitive control panel, the Small Single Shaft Shredder offers straightforward operation, allowing users to easily adjust settings to meet specific processing needs. Safety features, such as emergency stop functions and overload protection, are integrated to ensure a secure working environment for operators.

Durable and reliable, our Small Single Shaft Shredder is designed for longevity and efficiency, providing excellent value for businesses looking to enhance their waste management and recycling capabilities. Invest in this versatile machine today and contribute to a more sustainable future!

-

Product Features

High yield

Low cost

Convenient maintenance

Safer

More use-friendly

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, convenient maintenance, safer and more use-friendly.

2. The body adopts a special steel welded structure, which is more sturdy and has strong tearing ability. The rotor adopts a V-shaped design, driven by a hard tooth reducer, with high torque and low speed.

Applied Materials

Suitable materials for processing include:

-

Working Principle

1. Feed Hopper:

Put the material to be crushed, so as to prevent the material from splashing out.

2. Single Shaft Cutting System:

Using different blades according customers' material.

3. Power System:

We choose famous brands of motor in china, can also be configured according tocustomer needs.

4. Discharging Conveyor System:

Lt adopts independent power system, and that power system isintegrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

-

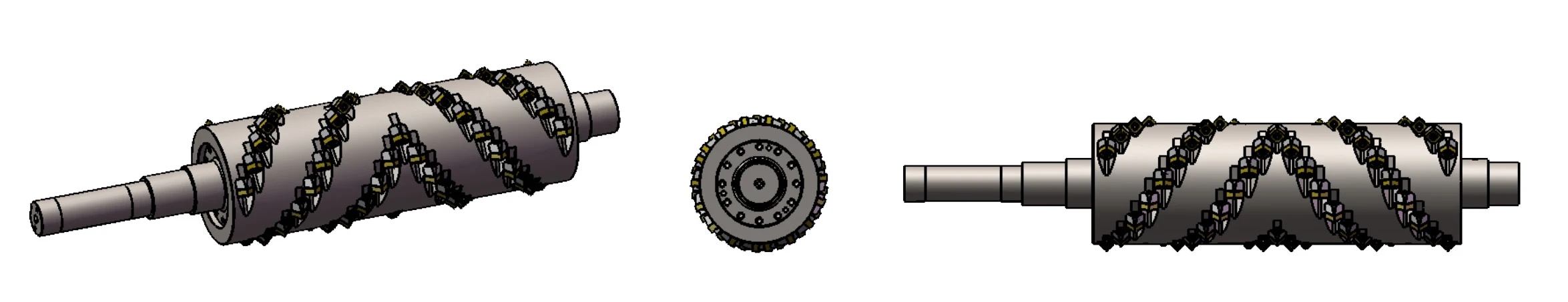

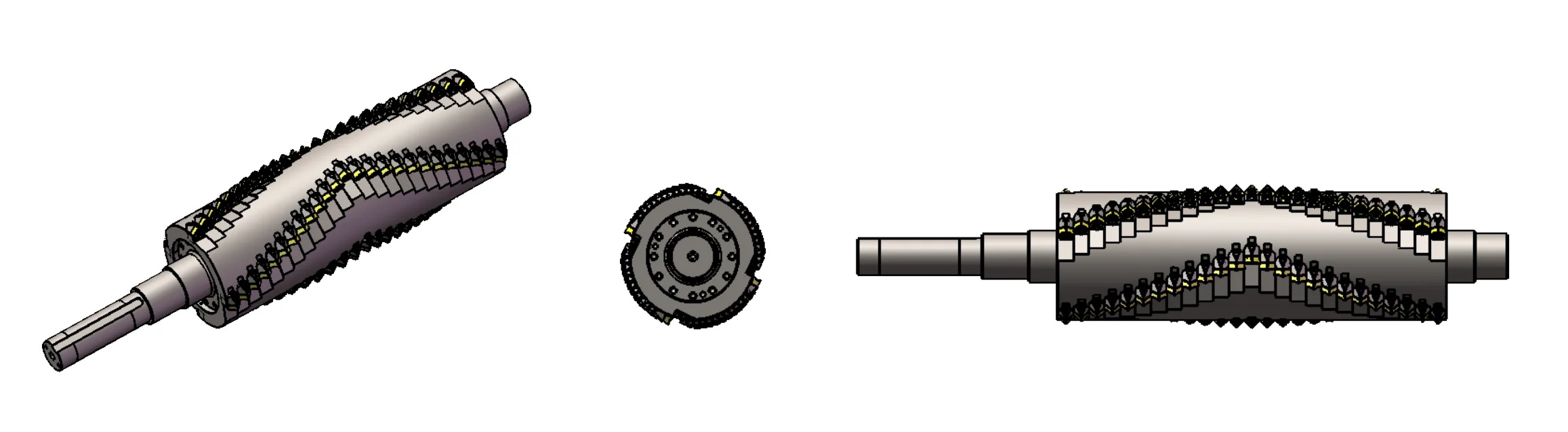

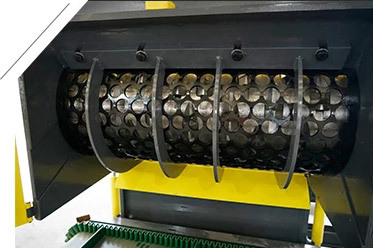

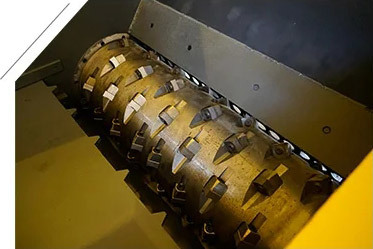

Single Shaft Shredder Mould Display

1. Staggered knife:suitable for similar head material and other materials 2.Tight alignment with small Angle:for easily wound materials

2.Tight alignment with small Angle:for easily wound materials 3.Tight arrangement Angle:suitable for packing tape and other soft materials

3.Tight arrangement Angle:suitable for packing tape and other soft materials

-

Product Details

01 Reducer

The gearbox adopts a well-knownbrand gearbox and rubbershock absorption device, whichattenuates the vibration generat-ed during the tearing process,absorbs the impact, and ensuressmooth tearing, protecting thesafety of the gearbox and itspower system.

02 Screen

According to different needs, dif-ferent mesh sizes can be replaced.The replacement of the screenis driven by hydraulic pressure,which better solves the shortageof manpower and the safety haz-ards caused by the replacementof the screen.

03 Hydraulic Pressure

Adopting a dual oil cylinderbalanced pushing system with ad-justable speed hydraulic system,the pushing and returning speedcan be freely adjusted accordingto the nature of the material.Equipped with an air coolingdevice to ensure the oil tempera-ture of the hydraulic system andmeet the continuous working.

04 Rotor

The moving knife adopts aV-shaped arrangement, whichcan be used multiple times atdifferent angles, effectively ensur-ing the long-term stability of theknife roll. Adjustable fixed tool:By adjusting the gap betweenthe tools, the material dischargeeffect can be controlled.

-

Product Application

Pre

best double shaft shredder machine

Exhibition

Recommended products

Message

Looking forward to communicating with you, a demand is the beginning of our understanding of you, but also the beginning of our establishment of cooperation.