Best Twin Shaft Shredder Machine

Category:

Summary:

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, easy maintenance, safer, and more uerfriendly. 2. The crushing chamber adopts special materials and welding processes, making the machine structure more sturdy and with strong tearing ability. The blade is designed with high-quality alloy steel, and the rotor transmission is driven by a planetary reducer, with high torque and low speed to ensure smooth operation.

Keywords:

Plastic recyling machine

Service:

Best Twin Shaft Shredder Machine

Details

- Technical parameters

- Features

- Working Principle

- Mould display

- Details

- Application

-

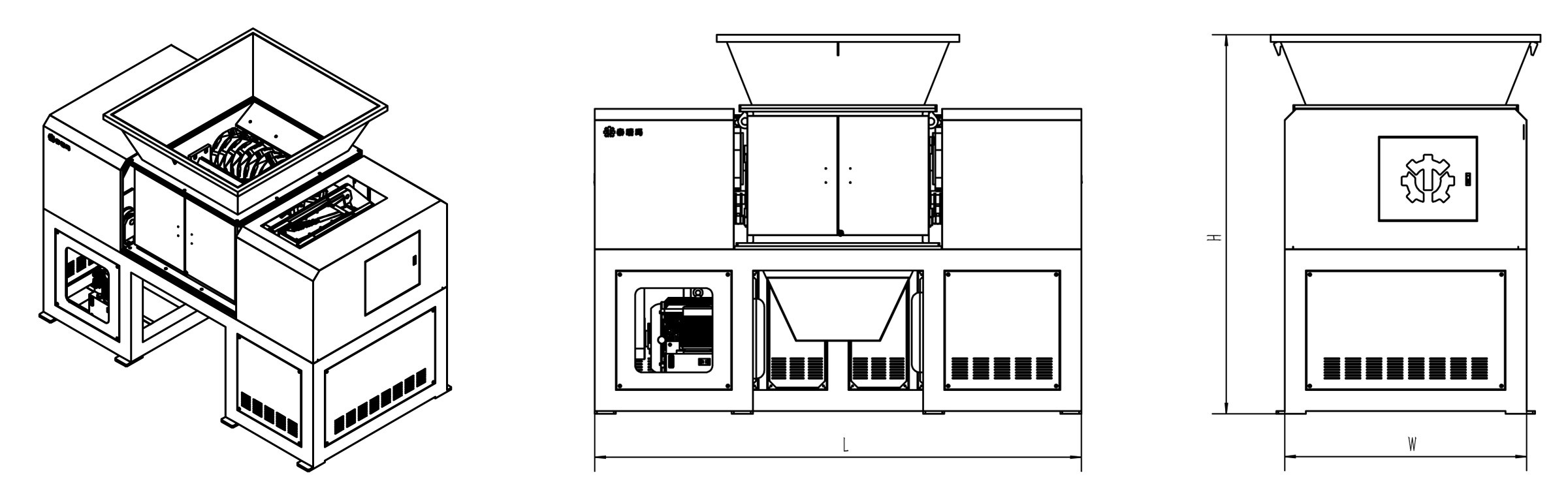

- Commodity name: Best Twin Shaft Shredder Machine

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, easy maintenance, safer, and more uerfriendly. </br> 2. The crushing chamber adopts special materials and welding processes, making the machine structure more sturdy and with strong tearing ability. The blade is designed with high-quality alloy steel, and the rotor transmission is driven by a planetary reducer, with high torque and low speed to ensure smooth operation.

HSG series technical parameters

MODEL\SPEC HSG800 HSG1000 HSG1200 HSG1600 Rotor diameter(mm) φ420 φ420 φ420 φ420 Roto width(mm) 800 1000 1200 1600 Main shaft speed(rpm) 38 38 38 38 Stator knives(pcs) 4 6 8 8 Rotor knives(pcs) 72 96 112 144 Motor power(kw) 37x2 55x2 75x2 90x2 Hydraulic power( kw) 1.5 1.5 1.5 1.5 Screen holes diameter(mm) >30 >30 >30 >30 Machine dimensions(mm) 3000x1750x2700 3200x1750x2700 3500x1750x2700 5000x1900x2700 Weight( kg) 5000 7000 9500 15000 MODEL HSG800 HSG1000 HSG1200 HSG1600 L 3000 3200 3500 5000 W 1750 1750 1750 1900 H 2700 2700 2700 2700

Twin Shaft Shredder has the following features:

Dual-axis design: two rotating axes cooperate with each other to effectively shred various materials.

Efficient shredding: with powerful shredding ability, materials can be quickly broken into smaller particles.

Widely applicable: suitable for processing various waste materials, such as plastics, wood, rubber, etc.

High stability: sturdy structure, stable operation, and long-term continuous work.

Easy to operate: easy to operate and maintain, reducing labor costs.

Energy saving and environmental protection: low noise and relatively low energy consumption during operation.

Safe and reliable: equipped with safety protection devices to ensure the safety of operators.

Twin Shaft Shredder has a wide range of applications in many industries, including:

Waste material recycling: effective crushing of various waste items.

Plastic processing: crushing plastic products for subsequent processing.

Wood processing: can be used for the treatment of wood waste.

Garbage disposal: helps to reduce the volume of garbage and facilitates transportation and disposal.

The Best Twin Shaft Shredder Machine is a highly versatile, efficient, and powerful solution for shredding a wide range of materials, including plastics, metals, rubber, paper, wood, and electronic waste. Designed for both industrial and commercial applications, this shredder is known for its exceptional durability, superior cutting capabilities, and advanced technology.

Equipped with two robust shafts that rotate in opposite directions, the twin shaft design ensures a more consistent and controlled shredding process. This configuration allows the shredder to handle tougher materials with ease, minimizing the risk of jams and increasing throughput. The twin shaft shredder machine is perfect for handling large volumes of waste, producing uniform-sized shredded particles that are ideal for recycling, disposal, or further processing.

Our twin shaft shredder machine is built with high-quality, wear-resistant materials, making it highly durable and capable of withstanding harsh conditions. It comes with adjustable knife configurations to optimize performance based on the type of material being processed. Additionally, the machine features an easy-to-use control panel, ensuring smooth operation and minimal downtime.

Safety is a priority with our Best Twin Shaft Shredder Machine, as it includes advanced features such as overload protection, emergency stop buttons, and automatic shutdown mechanisms. It's also designed for low maintenance, with easily accessible parts for routine checks and repairs.

Ideal for recycling facilities, waste management industries, and manufacturing plants, our Best Twin Shaft Shredder Machine provides an efficient, cost-effective, and environmentally-friendly solution for large-scale material reduction.

-

Product Features

High yield

Low cost

Convenient maintenance

Safer

More use-friendly

1. Adopting new design ideas and concepts, pursuing a design philosophy of high yield, low cost, convenient maintenance, safer and more use-friendly.

2. The body adopts a special steel welded structure, which is more sturdy and has strong tearing ability. The rotor adopts a V-shaped design, driven by a hard tooth reducer, with high torque and low speed.

Applied Materials

Suitable materials for processing include:

-

Working Principle

1. Feed Hopper:

Put the material to be crushed, so as to prevent the material from splashing out.

2. Twin Shaft Cutting System:

Using different blades according customers' material.

3. Power System:

We choose famous brands of motor in china, can also be configured according tocustomer needs.

4. Discharging Conveyor System:

Lt adopts independent power system, and that power system isintegrally fixed on the shredder by bolts, so that the power system can be integrally drawn out.

-

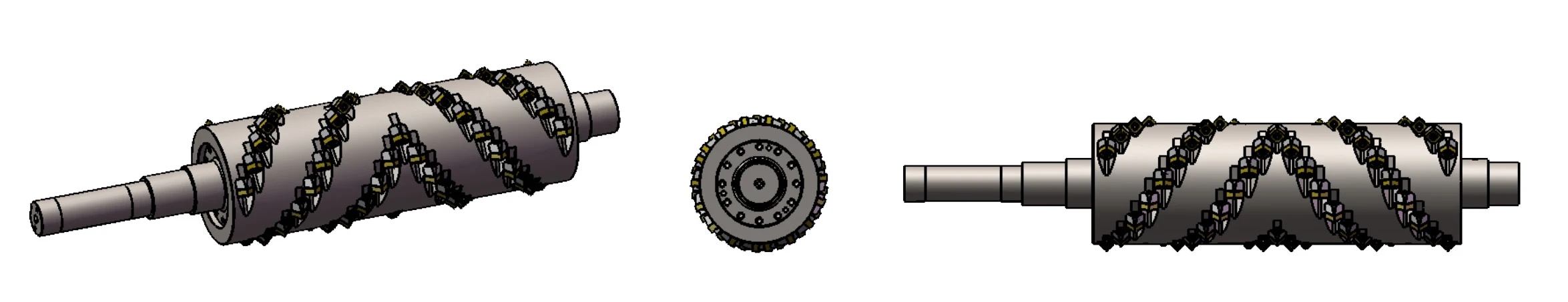

Twin Shaft Cutting System

1. Staggered knife:suitable for similar head material and other materials 2.Tight arrangement Angle:suitable for packing tape and other soft materials

2.Tight arrangement Angle:suitable for packing tape and other soft materials

-

Product Details

01 Sieve Mesh

According to different needs, dif-ferent mesh sizes can be replaced.The replacement of the screenis driven by hydraulic pressure,which better solves the shortageof manpower and the safety haz-ards caused by the replacementof the screen.

02 Reducer

The gearbox adopts a well-knownbrand gearbox and rubbershock absorption device, whichattenuates the vibration generat-ed during the tearing process,absorbs the impact, and ensuressmooth tearing, protecting thesafety of the gearbox and itspower system.

03 Rotor

The rotor blades adopt a disc type,effectively avoiding local damageand eliminating the need for com-plete replacement, thereby reduc-ing costs.There is no pushing device struc-ture, and the moving knives aretightly arranged to avoid materialentanglement.

-

Product Application

Pre

Pre

quality tyre shredder machine

Exhibition

Recommended products

Message

Looking forward to communicating with you, a demand is the beginning of our understanding of you, but also the beginning of our establishment of cooperation.